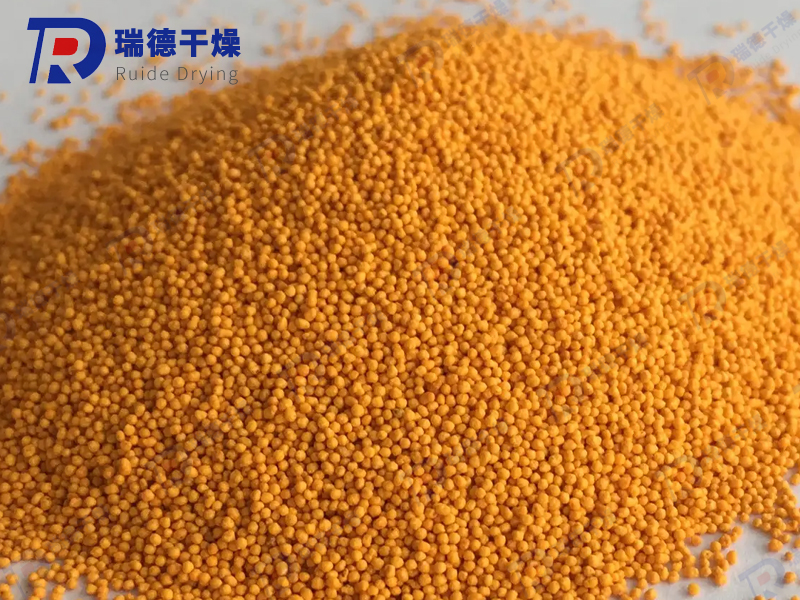

The powder material used for granulation is placed into a fluidized bed, and the material powder particles are in a circular fluidized state in the raw material container. They are preheated and mixed by purified heated air, and the adhesive solution is atomized and sprayed in, causing several particles to aggregate into clusters containing adhesive. Due to the continuous drying of the material by the hot air, the moisture in the clusters evaporates, and the adhesive solidifies. This process is repeated continuously to form ideal and uniform multi microporous spherical particles.

1. Improve flowability and reduce dust flying through powder granulation;

2. Improve its solubility through powder granulation;

3. Mixing, granulation, and drying in one machine to complete one-step granulation process;

4. Using anti-static filter cloth ensures safe operation of the equipment;

5. Explosion proof type with pressure relief holes, once an explosion occurs, equipment personnel will not be injured;

6. The equipment has no dead corners, and the loading and unloading of materials are lightweight and fast. It is cleaned thoroughly and meets GMP standards.

Granulation in the pharmaceutical industry: tablet granules, granule granules, capsule granules.

Granulation in the food industry: cocoa, coffee, milk powder, granulated fruit juice, seasonings, etc.

Granulation in other industries: pesticides, feed, fertilizers, pigments, dye chemicals, etc.

Drying of wet materials in powder or granular form.

Coating: granule, pill protective layer, coloring, sustained-release, film, enteric coating, etc.

Modle | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 |

Capacity L | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 530 | 660 | 1000 | 1500 |

Processing capacity kg | 1.5/4.5 | 4/6 | 10/20 | 15/45 | 25/65 | 40/80 | 60/120 | 80/160 | 90/200 | 100/300 | 150/450 | 250/750 |

Fan power kw | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 37 |

Steam consumption kg/h | 12 | 23 | 42 | 70 | 99 | 141 | 169 | 211 | 251 | 282 | 366 | 451 |

Compressed air consumption m3/min | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.3 | 1.5 |

Noise dB(A) | (Fan isolation installation)≤75 | |||||||||||

External dimensions m | 1.0 ×0.55 ×1.8 | 1.2 ×0.6 ×2.1 | 1.25 ×0.9 ×2.1 | 1.6 ×0.9 ×2.3 | 1.65 ×1.1 ×2.4 | 1.85 ×1.25 ×3 | 1.85 ×1.25 ×3 | 2.2 ×1.65 ×3.1 | 2.27 ×1.72 ×3.1 | 2.34 ×1.9 ×3.5 | 2.8 ×1.9 ×3.8 | 3 ×2.55 ×4.2 |

Note: The above parameters are for reference only and are subject to change without prior notice.

Previous:none!