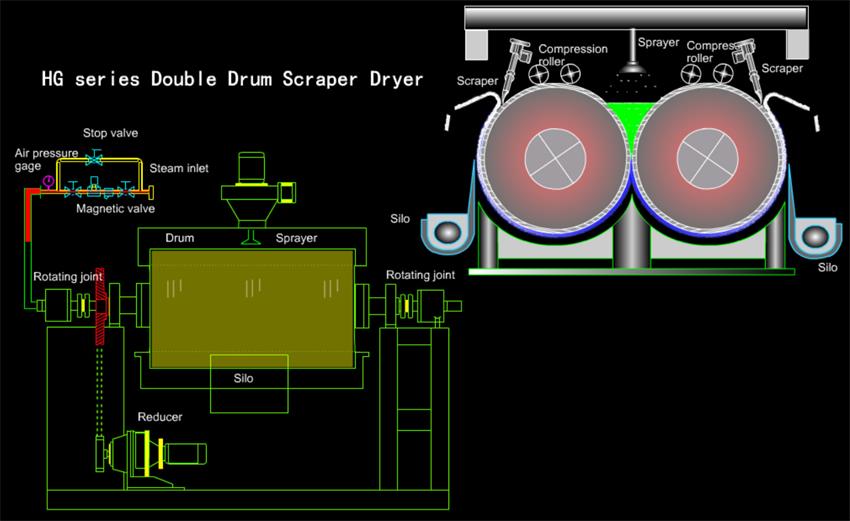

The HG series drum scraper dryer is an internally heated conductive rotary drying equipment. Wet materials obtain heat transferred through thermal conduction on the outer wall of the drum, removing moisture to achieve the required moisture content. The heat is transferred from the inner wall of the cylinder to the outer wall, and then passes through the material film. It has high thermal efficiency and can be operated continuously, so it is widely used for drying liquid or strip materials, and is more suitable for paste and viscous materials.

Liquid or slurry like materials form a thin film on the surface of a drum heated by steam or other heat carriers, and are dried during one rotation of the drum. The product is scraped off using a scraper, exposing the drum surface and coming into contact with the raw materials again to form a thin film for drying.

1. High thermal efficiency. The heat transfer mechanism of the drum scraper dryer belongs to thermal conduction, and the direction of heat transfer remains consistent throughout the entire operation cycle. Except for cover heat dissipation and thermal radiation loss, all other heat is used for the evaporation of the wet material film on the cylinder wall, and the thermal efficiency can reach 70% -80%.

2. High operational flexibility and wide applicability. Various drying factors of the adjustable drum dryer, such as feed concentration, coating film thickness, heating medium temperature, drum rotation speed, etc., can all change the drying efficiency of the drum dryer, and these factors are not interrelated. This brings great convenience to the operation of the drum dryer, enabling it to adapt to the drying of various materials and different production requirements.

3. Short drying time. The drying cycle of materials is generally only 10-300 seconds, which is suitable for heat sensitive materials. If the drum dryer is set in a vacuum chamber, it can operate under reduced pressure conditions.

4. High drying rate. Due to the thin film applied to the cylinder wall, usually between 0.3-1.5mm, and the consistent direction of mass transfer, the surface of the film can maintain 20-70kg The evaporation intensity of H2O/m2. h.

It can be divided into two forms: single cylinder and double cylinder dryers. Additionally, it can be divided into two forms based on operating pressure: normal pressure and reduced pressure.

The HG series drum scraper dryer is widely used in industries such as chemical, dye, pharmaceutical, food, metallurgy, etc. for the production and drying of liquid or viscous, paste like materials.

Note: If required by the customer, we can design and manufacture an upper feeding double drum dryer for them.