GHJ high-speed mixer is widely used for dry powder mixing in industries such as pharmaceuticals, food, chemicals, electronics, etc. It is particularly suitable for mixing materials with high uniformity requirements and large differences in material density. This machine has the characteristics of compact structure, easy operation, beautiful appearance, small footprint, and good mixing effect.

The vertical high-speed and high-efficiency mixer is a device specially developed for mixing powder materials, which solves the process problem of uneven wet mixing of various powder raw materials with water in industries such as food and pharmaceuticals. Widely used for mixing and stirring seasonings and other pharmaceutical, food, chemical raw material powders or granular materials.

1、Mixing evenly, there are no small clumps or pieces found at all;

2、Short mixing time, only 3-10 minutes per mixing time;

3、Feeding and discharging are very convenient, and cleaning is simple;

4、The sealing structure of this device has been carefully designed, with reliable sealing performance and easy maintenance and disassembly. All gears have undergone heat treatment, resulting in a long service life.

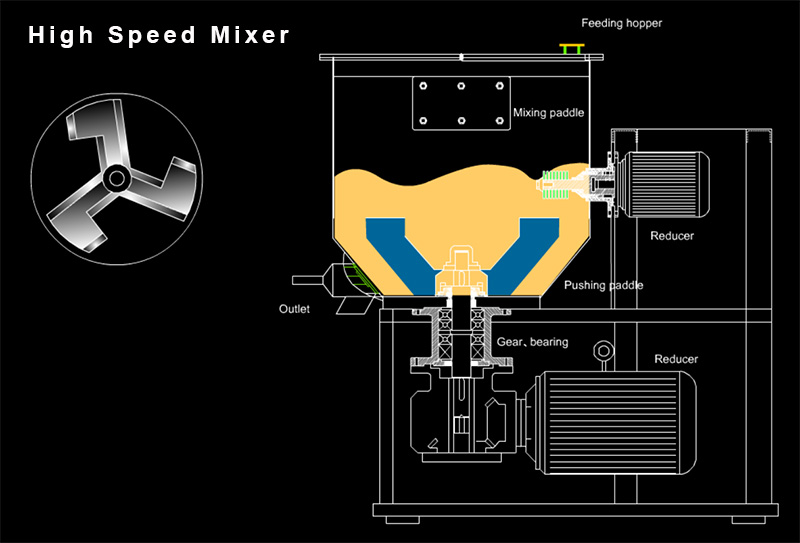

1. This machine adopts a horizontal cylindrical structure consisting of a frame, a mixing bucket, a mixing slurry, a cutting knife, and other components

2. The mixer continuously pushes the material upwards from the bottom mixing slurry during operation, and then cuts and decomposes it through the middle cutting knife. It repeatedly pushes and cuts the mixture in the mixing bucket, achieving the goal of fast, efficient, and uniform mixing. This machine has been improved on the basis of previous technology. The upper cover is made of stainless steel plate, which allows for a large opening range for easy feeding and cleaning. The connection between the round head and the mixing bucket is sealed with a silicone rubber sealing strip to effectively prevent material leakage during mixing. When the upper cover is opened, it can be supported and fixed with a support rod, which is easy to use and operate.

3. The internal seal of the mixing bucket adopts an inflatable seal. During the rotation of the main shaft, gas is continuously blown out from the inside out below the main shaft, and the material cannot enter the bearing during mixing, thus achieving a good sealing effect and prolonging the service life of the equipment.

4. The opening method of the discharge port face is pneumatic or manual. The door panel is made of two layers of stainless steel plates. When closing the door panel, the inner wall of the door panel is flat with the inner wall of the cylinder. A sealing strip is added to the outer layer of the door panel to provide better sealing during mixing and cleaning,

5. The electrical control box is well sealed, dust-proof, moisture-proof, and improves the safety performance of electrical control. It is easy to set up and operate.

6. The cylinder of this equipment is made of high-quality stainless steel, and the bracket is wrapped in stainless steel. Both the inside and outside are precision polished, with a smooth and easy to clean surface, no dead corners, and in compliance with GMP requirements.

Previous:SET Type Extrusion Granulator