It is particularly suitable for dehydrated vegetables, traditional Chinese medicine decoction pieces, and other materials with high moisture content and heat sensitivity. It has the advantages of high drying rate, high evaporation intensity, and good product quality. Belt dryers are widely used in industry, mainly for drying small pieces of materials and fibrous materials. In short, materials dried with a belt dryer must have a certain shape and still maintain a certain shape after drying.

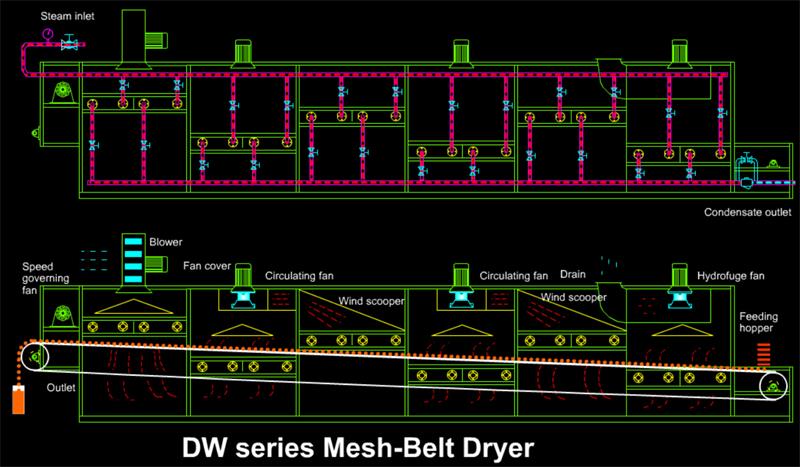

The material is evenly spread on the net belt by the feeder, and the net belt is made of 12-60 mesh stainless steel wire mesh. It is moved in the dryer by the drive. The dryer is composed of a number of units, each unit independent circulation of hot air, part of the exhaust gas is discharged by the special exhaust fan, the exhaust gas is controlled by the regulating valve, the hot gas from the bottom up or from the top down through the material on the net belt, heating and drying and taking away water. The mesh belt moves slowly, the running speed can be freely adjusted according to the temperature of the material, and the finished product after drying falls into the feeder continuously. The upper and lower cycle units can be flexibly equipped according to user needs, and the number of units can be selected according to needs.

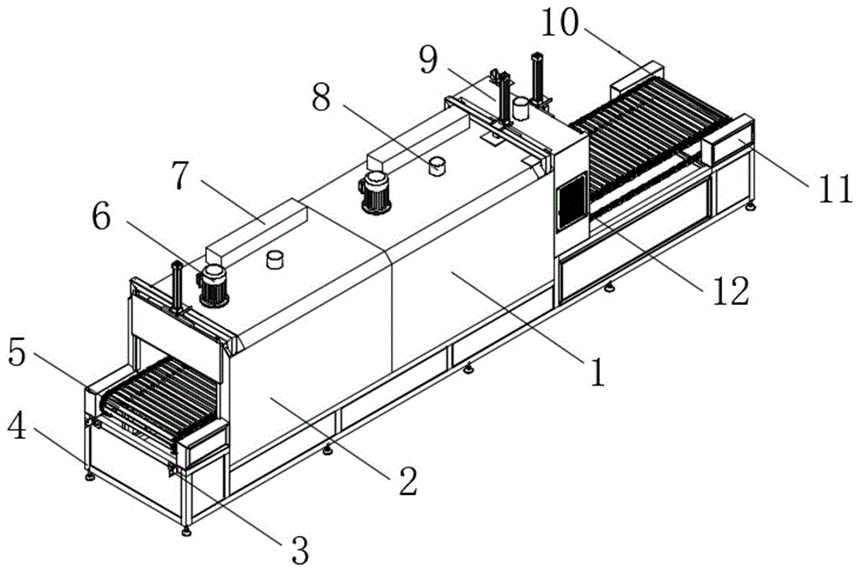

The material in the hopper is evenly spread on the net belt by the feeder, and the net belt is generally made of 12-60 mesh stainless steel mesh, which is dragged by the transmission device to move in the dryer. The dryer is composed of a number of units, each unit of the hot air independent circulation, part of the exhaust gas is discharged by the special exhaust fan 4, each unit exhaust gas volume is controlled by the regulating valve. In the upper circulation unit, the air coming out of the circulating fan 5 enters the lower chamber of the unit through the side air duct, and the air flow is heated upward through the heater 7. After being distributed by the distributor 6, the jet stream blows to the mesh belt and enters the upper chamber after passing through the material. The drying process is a process in which the hot air flows through the material layer to complete the transfer of heat and mass. The upper chamber is connected with the inlet of the fan by the air duct. Most of the gas circulates, and some of the gas with low temperature and large moisture content is discharged as waste gas through the moisture exhaust pipe, regulating valve and moisture exhaust fan. In the lower circulation unit, the air from the circulating fan first enters the upper chamber, is heated down by the heat exchanger, passes through the material layer into the lower chamber, and the lower chamber is connected with the fan by the side air duct and the return air duct, most of the gas is circulated, and a part is discharged. Upper and lower cycle units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

It is used for dewatering vegetables. Generally, three devices are used in series to form the initial dry section, the middle section and the final dry section. In the initial dry section, due to the high water content of the material. Poor permeability, so the use of small ply thickness, faster running speed and higher drying temperature. In the initial dry section, the dry gas temperature can be as high as 120oC or more. The residence time of the material in the final dry section is 3-6 times that of the initial dry section, and the thickness of the material is 2-4 times that of the initial dry section. For the requirements of material temperature not exceeding 60oC, dry gas of about 80oC can be used. The use of multi-stage combination can better play the performance of the belt dryer, and the drying is more uniform.

(1) Single-stage belt dryer: the material to be dried is evenly distributed to the conveyor belt from the feeding end through the feeding device. The conveyor belt is usually made of perforated stainless steel sheet, driven by a motor through a gearbox, which can be adjusted for speed. The body of the drying chassis is usually divided into several units to independently control operating parameters and optimize operation. There is an isolation section between the drying sections, in which no drying medium circulates.

(2) Multi-stage belt dryer: multi-stage belt drying is essentially composed of several single-stage belt drying machines in series, and its operating principle is the same as that of single-stage belt drying machines. (3) Multi-layer belt dryer: Multi-layer belt dryer is often used for occasions where the drying speed is low, the drying time is long, and the process operating conditions can be kept constant during the entire drying process. A partition is arranged between the layers to organize the directional flow of the drying medium and make the material dry evenly. Multi-layer belt dryer occupies a small area, simple structure, and is widely used in drying grain materials. However, due to multiple loading and unloading during the operation, it is not suitable for materials that are dry and easy to stick to the conveyor belt and do not allow fragmentation.

(4) Impact belt dryer: Impact belt dryer is suitable for drying fabric, tobacco, substrate surface coating and other sheet materials. The impact belt machine usually consists of two conveyor belts. The impact belt can be separated into unit segments for independent control. After the drying medium is humidified, part of it is discharged, and the other part is returned to the fresh drying medium and then recycled.

The use of belt dryers is wide, and it has been used in pharmaceutical, food, biological, chemical and other fields. However, the selection standards in each field are not the same, because the requirements and parameters of dry materials in various fields are quite different. For example, in the pharmaceutical industry (especially Chinese medicine), the general viscosity of the extract is large, and the drying temperature requirements are stricter, the melting point control should be accurate (especially the polysaccharide materials), the control range of the vacuum degree should meet the requirements of the heating temperature of different sections and have online automatic adjustment function. In addition, the testing system should be as perfect as possible to comply with pharmaceutical GMP standards. For the food industry, the solid content of the material extract is generally relatively large (more than 65%), the output requirements and the specific volume and appearance of the product are the key to the selection standard of the vacuum belt dryer, and there are two elements in the selection process of the food-grade vacuum belt dryer that must not be ignored: One is the consumption ratio of unit energy consumption, and the other is the supporting equipment such as the pre-delivery of raw materials, the fine crushing of dried products and packaging. As for the vacuum belt dryers used in biology and chemicals, due to the different forms of products, the selection standards are extremely complex, so extra caution is needed.

The first step in choosing a vacuum belt dryer is to perform a small sample test on the drying material, which is very important. Therefore, for equipment suppliers, whether they have material testing equipment and experienced test personnel is the most direct way for customers to measure the true ability of manufacturers. Qualified vacuum belt dryer manufacturers are generally able to provide customers with a copy in the shortest possible time after material testing, including: Material actual evaporation, dynamic drying vacuum, drying temperature distribution, feed size, actual drying time, actual product production capacity, unit energy consumption ratio and other technical parameters report, convenient for customers to choose according to requirements to meet the production of equipment models and specifications.

The second step in choosing a vacuum belt dryer is to comprehensively examine the manufacturer's design level and manufacturing capacity. The manufacturer will generally provide a draft technical design scheme according to the customer's production indicators and working conditions on the basis of the material test report and a detailed statement of the design reasons in the scheme. The technical design scheme is an extremely important part of evaluating the manufacturer's capacity in vacuum belt drying mechanism, especially the manufacturer's design description of the key technologies of the equipment, such as: the design of the vacuum system, the design of the heating system, the design of the correction system, the design of the cleaning system and the design of the feeding and discharging system. Another aspect of manufacturing capability is to examine the actual use of the manufacturer's users. Customers can according to the user list provided by the manufacturer, ask to go to the site, if the manufacturer does have enough strength generally will not refuse the customer's reasonable requirements, and some can even provide multiple visit targets for customers to choose. It is generally difficult for enterprises with limited manufacturing capacity or low technical level to do so.

The third step in choosing a vacuum belt dryer is to examine the actual processing capacity and production scale of the manufacturer. Domestic enterprises with serialized design and production capacity will not exceed three, especially the annual output of more than 10 vacuum belt dryers (especially large or very large equipment with more than 6 layers of drying beds) is estimated to be only 1 to 2 manufacturers. Therefore, it is difficult for most domestic manufacturers to form the standardized processing of vacuum belt dryer parts, which provides customers with product maintenance and maintenance as well as the exchange of parts and accessories, which often directly affects the user's production efficiency, and due to the lack of practical experience, The mechanical structure of the equipment, the rationality of the configuration, the precision requirements of the manufacturing, etc., can not be considered very comprehensively. Due to the characteristics of large volume, many auxiliary equipment, high configuration requirements, and complex intermediate links, it is not easy to maintain the long-term stability of the operating state of the equipment. The price of this equipment is also relatively expensive, users are generally optimistic about its drying capacity and technical advantages and use a huge amount of procurement, so they hope to recover the cost as soon as possible to improve the economic benefits of enterprises. Therefore, when purchasing equipment, we must choose a manufacturer with scale, actual design and manufacturing experience and a reliable after-sales service guarantee system to rest assured, of course, the vacuum belt dryer provided by such a manufacturer is generally slightly higher in price, but for users, there is a sense of security in the use of customers must not be due to the desire for a moment of low prices and may affect the overall situation.

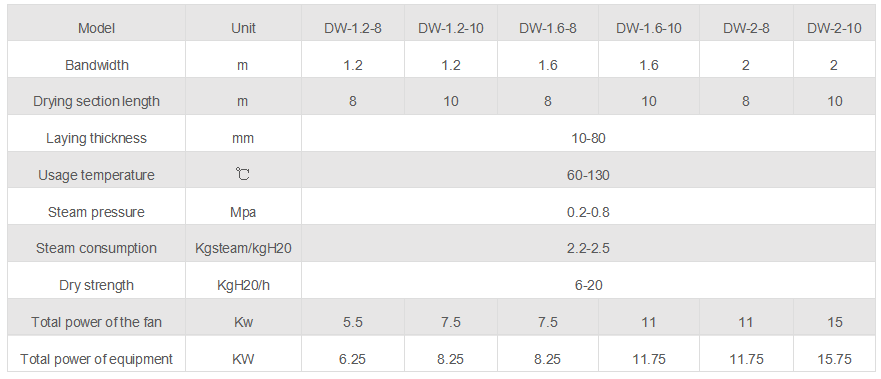

Used for drying sheet, strip, and granular materials with good breathability, especially suitable for dehydrated vegetables, traditional Chinese medicine decoction pieces, and other materials with high moisture content and material temperature not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For the paste like material of dehydrated filter cake, it can also be dried after granulation or shaping into a rod shape。

(1) The vibration and impact of the material on the dryer is slight, and the material particles are not easy to pulverize and break, so it is also suitable for drying some materials that do not allow fragmentation. (2) The dryer can not only dry the material, but also sometimes bake, burn or mature the material. (3) The structure of the dryer is not complicated, easy to install, can run for a long time, and can enter the internal maintenance of the box when failure occurs, and it is convenient to maintain.

(4) can adjust the amount of air, heating temperature, material residence time and feeding speed to achieve the best drying effect.

(5) The equipment configuration is flexible, and the mesh belt flushing system and material cooling system can be used.

(6) Most of the air is recycled, highly energy saving.

(7) The unique air distribution device makes the hot air distribution more uniform and ensures the consistency of product quality.

(8) The heat source can be steam, thermal oil, electricity or coal (oil) hot blast stove matching

Previous:KJG Series Hollow Blade Dryer