PLG series disc continuous dryer is a conductive continuous drying equipment, its structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, good operating environment and so on. Widely used in chemical, pharmaceutical, pesticide, food, feed, agricultural and sideline products processing industry drying operations. It has been well received in various industries.

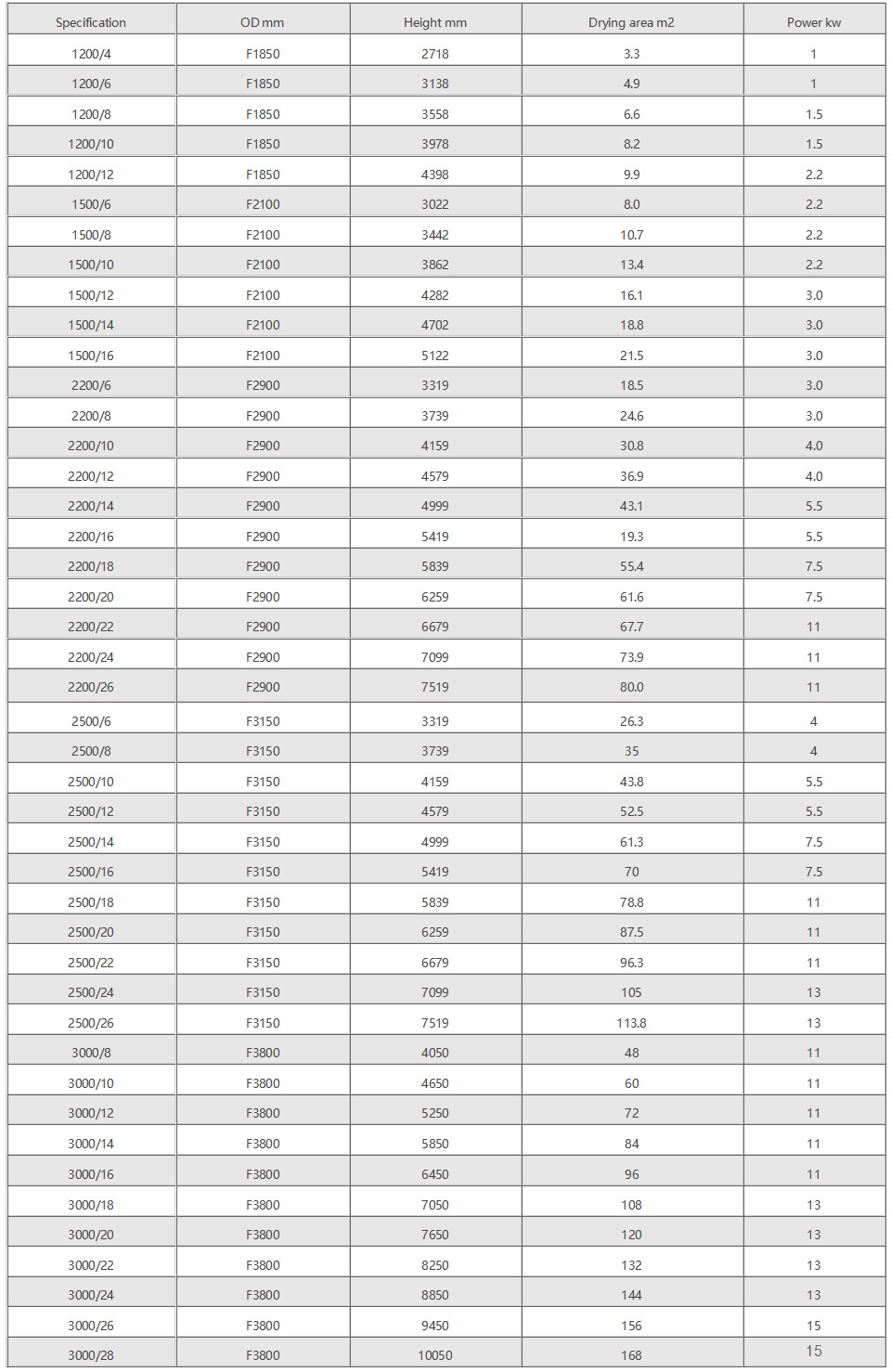

The disc drying equipment can be divided into three types: atmospheric pressure, closed and vacuum. 1200, 1500, 2200, 3000 four specifications; A (carbon steel), B(contact material part stainless steel), C on the basis of B, add steam pipe, spindle and support for stainless steel, cylinder and top cover lining stainless steel) three kinds of materials, drying area of 4 ~ 180m2, a total of hundreds of models of series products, and can provide supporting auxiliary equipment, can meet the needs of users for various materials drying.

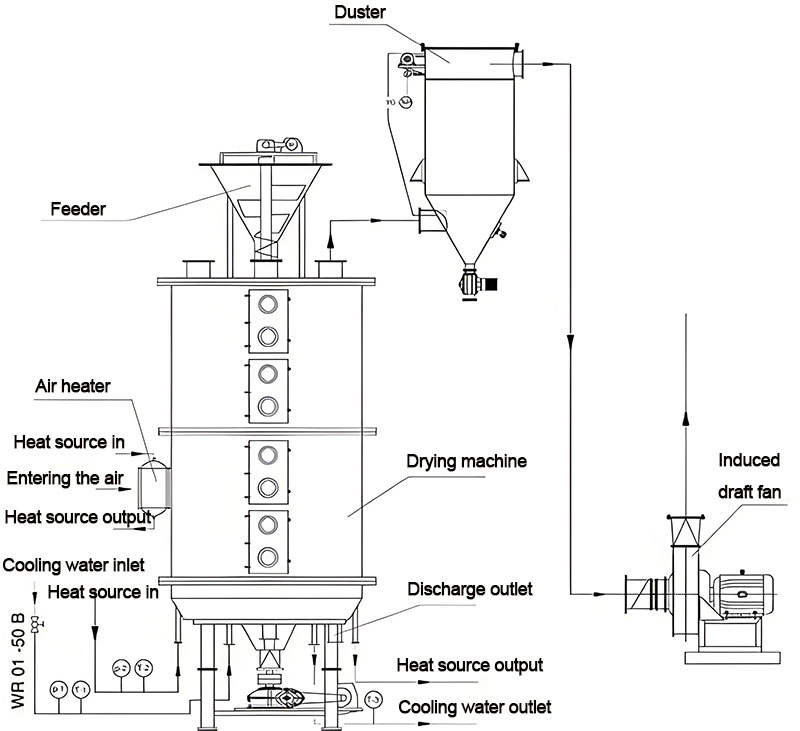

The wet material self-feeder is continuously added to the drying disc on the upper layer of the dryer, and the rake arm with the rake blade is rotated to make the rake blade continuously turn over the material. The material passes through the surface of the drying tray along the exponential helix, and the material on the small drying tray is transferred to the outer edge, and falls to the outer edge of the large drying tray below the outer edge, and the material moves inward on the large drying tower and falls into the next layer of small drying tray through the middle blanking port. The size of the drying tray is arranged alternately up and down, so that the material can flow continuously through the entire dryer. The heating medium in the form of saturated steam, hot water and heat conduction oil is passed into the hollow drying disc. The heating medium enters from one end of the drying disc and is exported from the other end. The dried material falls to the bottom of the shell from the last drying tray and is finally transferred to the discharge port by the rake leaf. Moisture escapes from the material. The moisture of the vacuum type disc dryer is extracted from the moisture outlet located on the top cover. Dry material discharged from the bottom layer can be packaged directly. By adding fin heater, solvent recovery condenser, bag dust collector, dry material remixing structure, induced draft fan and other auxiliary machines, it can improve its drying production capacity, heat sensitive materials, can easily recover solvent, and can carry out pyrolysis and reaction operations.

(1) Easy regulation and strong applicability

The drying process can be completed smoothly by adjusting the thickness of the material layer, the spindle speed, the number of rake arms and the size of rake wikstrobe.

Each layer of drying disc can be separately passed into the hot medium or cold medium, heating or cooling the material, the material temperature control is accurate and easy.

The residence time of the material can be precisely adjusted.

The material flow is single, no backmixing phenomenon, uniform drying, stable quality, no need to mix.

(2) Simple and easy operation

The dryer is very simple to start and stop.

After the feed is stopped, the transfer dirt rake can quickly empty the material in the dryer.

Through the special large-size view of the door mirror, the equipment can be carefully cleaned and observed.

(3) Low energy consumption

The material layer is very thin, the spindle speed is low, the system requires less power and less power consumption.

Conduction heat for drying, high thermal efficiency, low energy consumption.

(4) The operating environment is good, the solvent can be recovered, and the dust emission meets the requirements

Atmospheric pressure type: Because the airflow speed in the equipment is low, and the humidity in the equipment is low, the dust is difficult to float to the top of the equipment, so the exhaust gas discharged from the top exhaust temperature outlet almost does not contain dust.

Closed type: equipped with solvent recovery device, can easily recover the organic solvent in the wet gas. The solvent recovery device is simple, the recovery rate is low, for flammable, explosive, toxic and easily oxidized materials, nitrogen can be used as a wet gas halfway cycle, so that it is safe to operate. Especially suitable for the drying of flammable, explosive and toxic materials.

(5) Easy installation, small footprint

The dryer is delivered as a whole, transported as a whole, just need to be hoisted into place, and installation and positioning is very easy.

Due to the vertical layout of the drying tray layer and vertical installation, the drying area is large and the floor area is small.

Drying, pyrolysis, combustion, cooling, reaction, sublimation

(1) Organic chemical products

(2)Inorganic chemical products

(3)Pharmaceuticals and food

(4)Feed and Fertilizer;