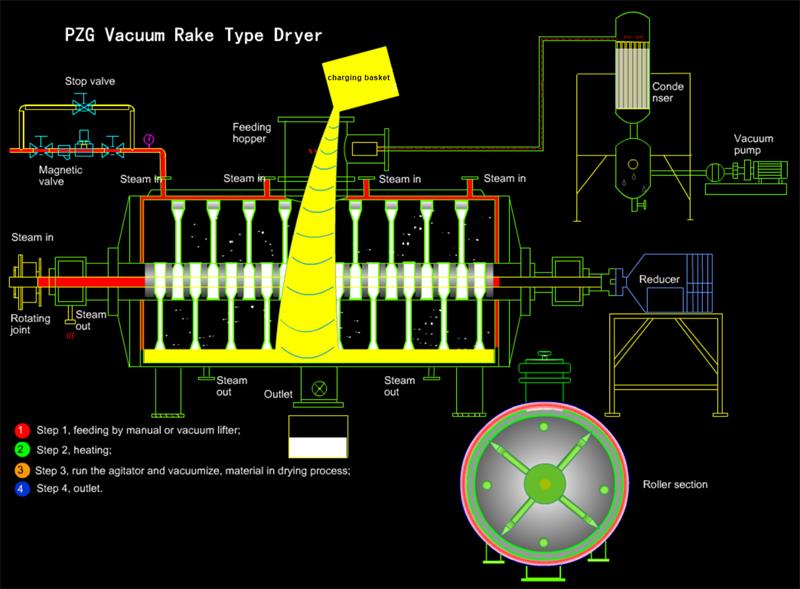

This machine is a novel horizontal intermittent vacuum drying equipment. Wet materials are evaporated through conduction, and a scraper stirrer is equipped to continuously remove the materials on the hot surface and move them inside the container to form a circulating flow. After the water evaporates, it is pumped out by a vacuum pump.

1、This machine adopts a large-area interlayer heating method, with a large heat transfer surface and high thermal efficiency.

2、The machine is equipped with agitation to create a continuous circulation of materials inside the cylinder, further improving the uniformity of material heating.

3、The machine is equipped with a mixing system, which enables smooth drying of slurry, paste, and paste like materials.

1、Drying of the following materials is carried out in industries such as pharmaceuticals, food, and chemicals;

2、Suitable for paste like, paste like, and powdery materials;

3、Thermally sensitive materials that require low-temperature drying;

4、 Materials that are prone to oxidation, explosion, strong irritation, and high toxicity;

5、Require the recycling of materials containing organic solvents.

(1) Strong adaptability: Widely used. Due to the use of jacket heating and high vacuum exhaust, the rake type vacuum dryer is almost suitable for all materials with different properties and states, especially for drying explosive, easily oxidized, and paste like materials.

(2) Good product quality: Due to the continuous forward and backward rotation of the rake teeth during the drying process, the dried material is stirred evenly, avoiding overheating of the material and making it easy for moisture to escape, resulting in a low-temperature product. Due to the fine particle size of the product, it can be packaged without crushing.

(3) Low steam consumption: Due to the fact that vacuum rake dryers often use steam to pass through the jacket and use latent heat to heat the material, the steam consumption per kilogram of finished product is relatively small, usually 1.3-1.8kg of steam.

(4) According to the different characteristics and requirements of dry materials, the sealing system of the dryer can choose between packing seal and mechanical seal. The special design ensures sealing performance and service life.

(5) Easy to operate: The vacuum rake dryer is easy to operate, has a small staffing requirement, and low labor intensity. Due to the reduction of material leakage losses, environmental hygiene has been improved. The main disadvantages of vacuum rake drying are complex structure and high cost. Due to intermittent operation, the drying time is long and the stock yield is low; Due to the difficulty in clearing materials, it is not suitable to frequently switch varieties in production. At the same time, in order to ensure the vacuum degree, it is necessary to regularly maintain and repair the vacuum device.

Previous:none!